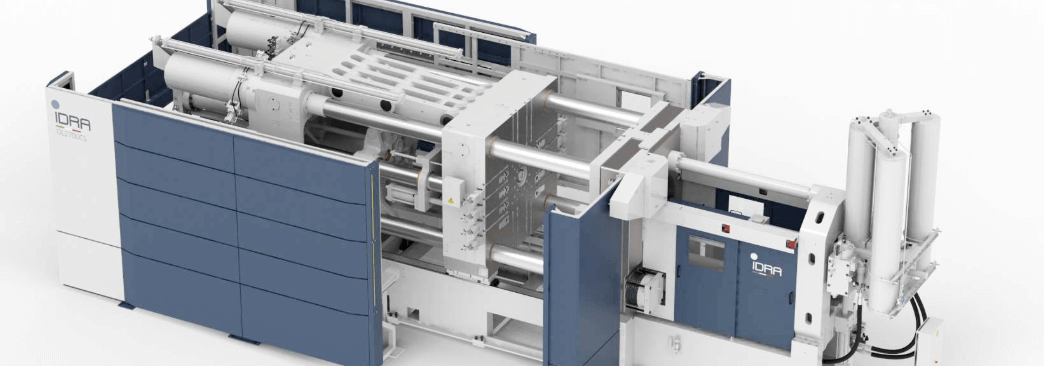

Continuing the IDRA reputation for innovation and development the OL CS takes 70 years of industry experience. OL CS condenses machinery is designed for foundry needs and the latest production requirements.

The compact mechanical structure and robust dimensions have been designed using the same criteria and characteristics that have always guaranteed long life and reliability for the foundry. Emphasis on the overall length of the machine ensures that the required floor space is equal to or better than the two platen product range.

Integrated high flow hydraulic manifold blocks and increased pump capacity ensure that the fast cycle times required can be achieved, whilst energy cost can be kept to a minimum by the use of energy efficient motors with speed control. The drastic reduction of external pipe work reduces the need for maintenance and minimises the risk of fluid loss.

Idra’s new OLS injection is equipped as standard with Parker closed loop meter out proportional valve, which has the same technical characteristics and response time as a servo valve. Parker valves combine the latest technology to reduce CO2 emissions and meet international environmental standards.