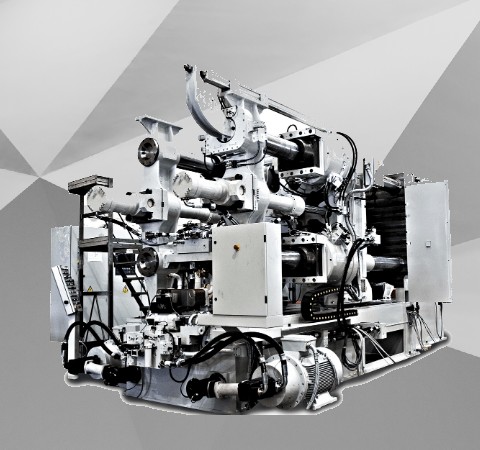

OL R machines represent a new generation of die press machine, with a shorterlength compared to similar toggle models and better distribution of tie bar load compensating die thermal expansion automatically.

The R range has been designed with integrated, modular and compact hydraulic manifolds with very few external pipes to eliminate fluid leaks and facilitate easy maintenance. The machine is environment friendly and remarkable for the low power consumptions since in its standard configuration it is equipped with control of the motors with frequency variators (inverters).

Machines from the R range can be supplied in standard conventional design as well in NOX design, with integrated holding furnace for metal transfer into the injection sleeve avoiding any atmosphere contact and consequent metal oxidation, suitable for heat treatable, weldable structural component production.